Trimerization catalyst

Trimerization catalyst

Highly efficient trimerization catalysts for aliphatic and alicyclic isocyanates

Polyurethane has excellent physical and mechanical properties and chemical stability, and is widely used in foams, coatings, elastomers, adhesives, leather and other fields, however, there are also defects such as poor heat resistance, low softening and decomposition temperatures, which limit its application in some fields. Later, it was found that aromatic or aliphatic isocyanates can be self-trimerized into isocyanurate under heating. Because the isocyanurate ring has a strong electron absorption effect, resulting in an increase in the polarity of the C=N bond of NCO in the molecule, thus increasing its reactivity, and hydroxyl reaction can be crosslinked and cured into a film, and the degree of crosslinking of the cured product increases within the appropriate range of the hardness increases, adhesion enhancement.

Polyurethane products containing isocyanurate ring have the following characteristics:

(1) Because of the high radiation resistance of the isocyanurate ring, the resulting polymer material has high protection against radiation.

② It has good corrosion resistance and anti-yellowing performance.

③Isocyanuric acid ring does not contain active hydrogen atoms and thus does not form hydrogen bonds, thus the isocyanate containing isocyanuric acid ester has low viscosity and high solid content.

④ The isocyanurate ring is very stable, so it is stored for a long time and has good heat resistance.

⑤ Since the isocyanurate ring contains flame-retardant nitrogen elements, the material made from it is flame-retardant.

Therefore, isocyanate trimer has been highly concerned, and has been applied in the fields of coatings, adhesives, sealants, elastomers, foam, etc. Applications have also been reported in the fields of textiles, papermaking, and printing ink.

Foreign industrial production of isocyanate trimers containing isocyanate from the 1970s, has formed a series of products, including the more famous manufacturers are HULS, Bayer, SAPICI company.

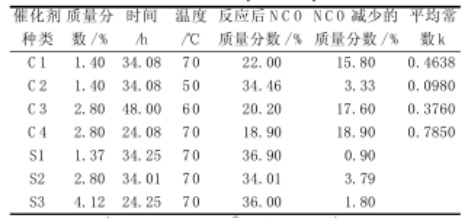

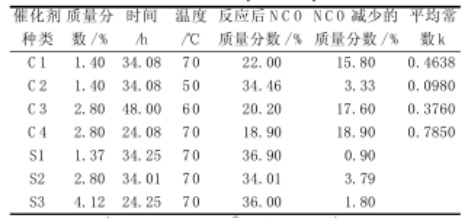

However, because of the low activity of aliphatic and alicyclic isocyanates, the preparation of aliphatic and alicyclic isocyanate trimers requires the addition of suitable catalysts for catalyzing in actual production. Different from the conventional TDI trimer preparation, conventional tertiary amine catalysts such as DMP-30 have little effect on the trimerization of aliphatic and alicyclic isocyanates, and conventional potassium metal salt catalysts have some effect on the trimerization of aliphatic and alicyclic isocyanates, but it is not enough to meet the requirements of actual production. In this regard, Song Chunmei from East China University of Science and Technology synthesized IPDI trimer with potassium acetate (Polycat 46) as catalyst at a certain temperature and compared it with 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30), and the results are shown in the table below:

C1-C4 are potassium acetate, S1-S3 are DMP-30

From the data in the above table, it can be seen that the catalytic effect of DMP-30 on IPDI trimerization is not obvious, and potassium acetate has effect on IPDI trimerization catalysis, but its conversion rate is not high.

In response to this situation, Xinden Chemical has developed a new type of polymerization catalyst NT CAT P200 after many years, which can effectively polymerize aliphatic and alicyclic isocyanates, and take IPDI as an example to do a comparative experiment:

Take 710 g of IPDI monomer in 1 liter four-necked flask with mechanical stirring. Rapid stirring under nitrogen protection was carried out and the reactor was heated to 85 °C. The catalyst NT CAT P200 was added separately, the temperature was maintained and stirring was continued for two hours, the samples analyzed by FTIR showed a conversion of 57%. The catalyst was deactivated by the addition of phosphoric acid and 700 g of essentially colorless reaction product was obtained. A product viscosity of 2200 mPa.s (25 °C) was obtained with an NCO% index of 28.6. The product was diluted by the addition of 84.7 g of IPDI monomer, and the viscosity of the diluted product was 730 mPa.s (25 °C). The distribution of oligomers as determined by GPC was 78.3% for trimers; 16.4% for pentamers; and 5.3% for heptamers and higher oligomers.

Experimental results show that: NT CAT P200 catalyst not only has high reactivity, but also has good selectivity, and also has great excellence in reducing the viscosity, color and odor of the product.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

sales@newtopchem.com |

Telephone: |

86-152 2121 6908 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |